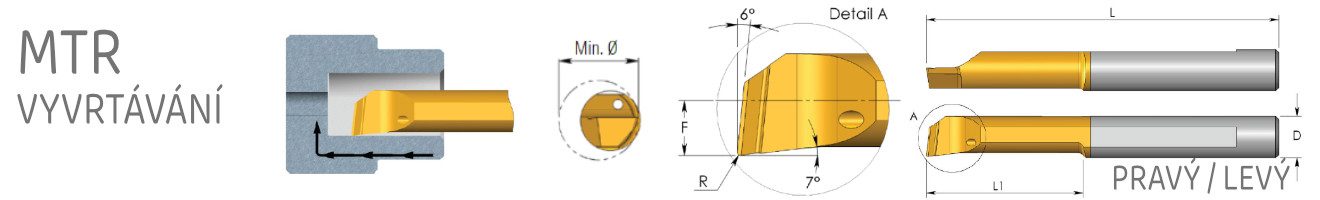

Nůž MTR - malý nástroj pro soustružnické operace

| Ø D mm | Objednací číslo | L mm | L1 mm | R rádius | F | Min. Ø | Držák |

|---|---|---|---|---|---|---|---|

| 3.0 | MTR 1 R0 L6 | 39 | 6 | 0 | 0.5 | 1.0 | SIM … H3 |

| 3.0 | MTR 1 R0.05 L4 | 39 | 4 | 0.05 | 0.5 | 1.0 | SIM … H3 |

| 3.0 | MTR 1 R0.05 L6 | 39 | 6 | 0.05 | 0.5 | 1.0 | SIM … H3 |

| 3.0 | MTR 1.2 R0 L7 | 39 | 7 | 0 | 0.6 | 1.2 | SIM … H3 |

| 3.0 | MTR 1.2 R0 L9 | 39 | 9 | 0 | 0.6 | 1.2 | SIM … H3 |

| 3.0 | MTR 1.5 R0 L6 | 39 | 6 | 0 | 0.7 | 1.5 | SIM … H3 |

| 3.0 | MTR 1.5 R0.1 L6 | 39 | 6 | 0.10 | 0.7 | 1.5 | SIM … H3 |

| 3.0 | MTR 2 R0 L10 | 39 | 10 | 0 | 0.8 | 2.1 | SIM … H3 |

| 3.0 | MTR 2 R0.05 L5 | 39 | 5 | 0.05 | 0.8 | 2.1 | SIM … H3 |

| 3.0 | MTR 2 R0.05 L10 | 39 | 10 | 0.05 | 0.8 | 2.1 | SIM … H3 |

| 3.0 | MTR 2 R0.1 L10 | 39 | 10 | 0.10 | 0.8 | 2.1 | SIM … H3 |

| 3.0 | MTR 2 R0.1 L15 | 39 | 15 | 0.10 | 0.8 | 2.1 | SIM … H3 |

| 3.0 | MTR 2 R0.15 L5 | 39 | 5 | 0.15 | 0.8 | 2.1 | SIM … H3 |

| 3.0 | MTR 2 R0.15 L10 | 39 | 10 | 0.15 | 0.8 | 2.1 | SIM … H3 |

| 4.0 | MTR 2.5 R0 L10 | 51 | 10 | 0 | 1.0 | 2.5 | SIM … H4 |

| 4.0 | MTR 2.5 R0.1 L10 | 51 | 10 | 0.10 | 1.0 | 2.5 | SIM … H4 |

| 4.0 | MTR 2.5 R0.1 L15 | 51 | 15 | 0.10 | 1.0 | 2.5 | SIM … H4 |

| 3.0 | MTR 3 R0.05 L10 | 39 | 10 | 0.05 | 1.3 | 3.1 | SIM … H3 |

| 3.0 | MTR 3 R0.05 L15 | 39 | 15 | 0.05 | 1.3 | 3.1 | SIM … H3 |

| 3.0 | MTR 3 R0.1 L10 | 39 | 10 | 0.10 | 1.3 | 3.1 | SIM … H3 |

| 3.0 | MTR 3 R0.1 L15 | 39 | 15 | 0.10 | 1.3 | 3.1 | SIM … H3 |

| 3.0 | MTR 3 R0.2 L10 | 39 | 10 | 0.20 | 1.3 | 3.1 | SIM … H3 |

| 3.0 | MTR 3 R0.2 L15 | 39 | 15 | 0.20 | 1.3 | 3.1 | SIM … H3 |

| 4.0 | MTR 4 R0.05 L15 | 51 | 15 | 0.05 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.05 L22 | 51 | 22 | 0.05 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.1 L10 | 51 | 10 | 0.10 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.1 L15 | 51 | 15 | 0.10 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.1 L22 | 51 | 22 | 0.10 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.2 L10 | 51 | 10 | 0.20 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.2 L15 | 51 | 15 | 0.20 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.2 L22 | 51 | 22 | 0.20 | 1.7 | 4.1 | SIM … H4 |

| 4.0 | MTR 4 R0.2 L30 | 62 | 30 | 0.20 | 1.7 | 4.1 | SIM … H4 |

| 5.0 | MTR 5 R0.05 L15 | 51 | 15 | 0.05 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.1 L15 | 51 | 15 | 0.10 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.1 L22 | 51 | 22 | 0.10 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.1 L30 | 76 | 30 | 0.10 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.2 L10 | 51 | 10 | 0.20 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.2 L15 | 51 | 15 | 0.17 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.2 L22 | 51 | 22 | 0.18 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.2 L30 | 76 | 30 | 0.20 | 2.1 | 5.1 | SIM … H5 |

| 5.0 | MTR 5 R0.2 L40 | 76 | 40 | 0.20 | 2.1 | 5.1 | SIM … H5 |

| 6.0 | MTR 6 R0.05 L15 | 51 | 15 | 0.05 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.1 L15 | 51 | 15 | 0.10 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.2 L15 | 51 | 15 | 0.20 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.2 L22 | 51 | 22 | 0.20 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.2 L30 | 58 | 30 | 0.20 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.2 L40 | 76 | 40 | 0.20 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.2 L30 | 58 | 30 | 0.20 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.2 L35 | 76 | 35 | 0.20 | 2.8 | 6.1 | SIM … H6 |

| 6.0 | MTR 6 R0.2 L40 | 76 | 40 | 0.20 | 2.8 | 6.1 | SIM … H6 |

| 7.0 | MTR 7 R0.2 L22 | 62 | 22 | 0.20 | 3.3 | 7.1 | SIM … H7 |

| 7.0 | MTR 7 R0.2 L30 | 62 | 30 | 0.20 | 3.3 | 7.1 | SIM … H7 |

| 8.0 | MTR 8 R0.2 L15 | 64 | 15 | 0.20 | 3.8 | 8.1 | SIM … H8 |

| 8.0 | MTR 8 R0.2 L22 | 64 | 22 | 0.20 | 3.8 | 8.1 | SIM … H8 |

| 8.0 | MTR 8 R0.2 L35 | 76 | 35 | 0.20 | 3.8 | 8.1 | SIM … H8 |

| 10.0 | MTR 10 R0.2 L35 | 73 | 35 | 0.20 | 4.8 | 10.1 | SIM … H10 |

Upozornění: pro LEVÝ NŮŽ nahraďte v objednávce MTL namísto MTR (R = pravý)

Příklad objednávky: MTR 4 R0.2 L15 BXC . . . 2 ks

BXC

BMK

K20

BXC

Karbid s povlakem na bázi TiN pro nízké řezné rychlosti. Vhodný pro širokou škálu korozivzdorných ocelí. Pro nízké až střední řezné rychlosti (ISO P30-P50 / K25-K40).

Příklad označení malých nástrojů: MTR 6 R0.1 L22 BXC

BMK

Velmi jemná struktura karbidu s třívrstvým PVD povlakem na bázi TiAlN (ISO K10-K20 / K20-K30). Extrémně vysoká teplná odolnost pro maximální výkony. Hladký průběh při operaci – závitování. Obecné použití pro všechny materiály.

Velmi jemná struktura karbidu s třívrstvým PVD povlakem na bázi TiAlN (ISO K10-K20 / K20-K30). Extrémně vysoká teplná odolnost pro maximální výkony. Hladký průběh při operaci – závitování. Obecné použití pro všechny materiály.

Příklad označení malých nástrojů: MUR 5 R0.15 L15 BMK

K20

Bez povlaku – karbid je určen pro neželezné kovy, hliník a litinu (ISO K10-K30)

Bez povlaku – karbid je určen pro neželezné kovy, hliník a litinu (ISO K10-K30)

Příklad označení malých nástrojů: MDR 6 R0.5 L27 K20